Due to the numerous rules and recommendations for

installation in the bearing area, the external dimensions of the different ball bearing manufacturers differ only in nuances. The large differences are evident

in the internal values of the ball bearing, the materials used for the rings

and seals, the number of balls and their diameter, the surface structure and

the precision of the profile, as well as the lubricant used.

350,000 RPM separable ball bearing GRW has, as required,

three different materials to choose from for ball bearing rings. You can choose

between 100Cr6, X65Cr13 (SS) or X35CrMoN15-1 (SV30).

Regardless of whether the customer's focus is on hardness, operating temperature or corrosion resistance, in the hardening process developed by GRW, the desired properties can be specifically invoked and implemented in the internal hardening workshop. In order to obtain additional functional properties of the bearing ring, coatings can also be provided.

Steel Tumbling Media, catalyst balls, forged steel grinding balls, forged steel balls, ceramic grinding media suppliers, Steel Tumbling Media, zirconium silicate beads, catalyst bed support balls

Regardless of whether the customer's focus is on hardness, operating temperature or corrosion resistance, in the hardening process developed by GRW, the desired properties can be specifically invoked and implemented in the internal hardening workshop. In order to obtain additional functional properties of the bearing ring, coatings can also be provided.

Steel Tumbling Media, catalyst balls, forged steel grinding balls, forged steel balls, ceramic grinding media suppliers, Steel Tumbling Media, zirconium silicate beads, catalyst bed support balls

For a long time, GRW has invested significant development

effort in the coating of ball bearings. The objective of this development is,

among other things, to improve tribological behavior or increase corrosion

resistance. Whether as a dry lubricant to increase dry running properties or

for high vacuum use, GRW offers the best solution for every requirement, with

now more than 90 different coating varieties. The most recent development in

this area is a hybrid band of metal and plastic (patent: EP000001832765B1). In

this way, a metal band is coated with a thin and solid PTFE sheet and then

formed into a steel tape retainer. Due to the low coefficients of PTFE

friction, ball bearings with the lowest friction moments and excellent dry

running life can be achieved with this retention liner.

For a long time, GRW has invested significant development

effort in the coating of ball bearings. The objective of this development is,

among other things, to improve tribological behavior or increase corrosion

resistance. Whether as a dry lubricant to increase dry running properties or

for high vacuum use, GRW offers the best solution for every requirement, with

now more than 90 different coating varieties. The most recent development in

this area is a hybrid band of metal and plastic (patent: EP000001832765B1). In

this way, a metal band is coated with a thin and solid PTFE sheet and then

formed into a steel tape retainer. Due to the low coefficients of PTFE

friction, ball bearings with the lowest friction moments and excellent dry

running life can be achieved with this retention liner.

In addition, the most recent procedures are used through PVD

(physical vapor deposition) or CVD (chemical vapor deposition) and meet the

highest standards of coating quality. An unwanted dissolution of the coating

will result in a serious early bearing failure. Therefore, all coating

varieties are subject to strict GRW standards and quality tests.

Torlon Snap Retainer The retainer must hold the balls at the

same distance from each other and avoid touching each other. In addition, the

retainer must have an appropriate design with defined material strengths and

balanced elasticity, to withstand the ball bearing load as well as possible.

In addition to the strict tolerance specifications for GRW

ball bearing rings with respect to surface finish, shape accuracy and steel

purity, the same requirements apply to the design and production of the

retainer. There are 3 basic variants for retainers: inner ring, outer ring or

ball-controlled retainer.

These basic types can be combined with 21 different

materials. The material selection covers the entire range, from metal tapes for

steel tape retainers to special aviation and spaceflight materials, to

chemically coupled “PAI - PTFE-cg” plastic for heavy applications for

applications with the most high standards of wear behavior, temperature

resistance and sterilization capacity.

grinding balls, milling media, shot peening media, grinding media, stainless steel tumbling media,steel tumbling media, alumina grinding balls, zirconium oxide beads

grinding balls, milling media, shot peening media, grinding media, stainless steel tumbling media,steel tumbling media, alumina grinding balls, zirconium oxide beads

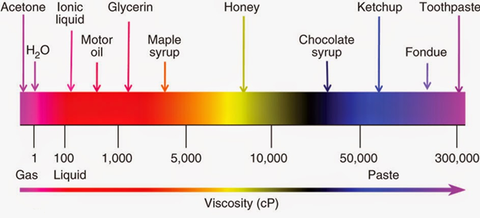

Lubricants serve to reduce friction and wear, as well as

cooling, shock absorption, sealing effect and corrosion protection. Lubrication

can be carried out using greases or oils and / or in special cases solid

lubricants. All 3 types are recovered in GRW products. The installation

situation of the ball bearing is crucial for the selection of a suitable

lubricant. Grease lubrication is recommended for general use at low to medium

speeds and, therefore, is the most commonly used type of lubrication. The main

part of the lubricating grease consists of base oil and the smallest part

consists of the appropriate thickener. The lubrication of the bearings is

mainly done with base oil, which releases the thickener in small amounts over

time. GRW uses lime soaps, natron soaps, lithium soaps and complex soapy fats.

Oil lubrication is used if grease lubrication cannot be used

for technical or economic reasons. This may be the case with high operating

temperatures, caused by ambient temperature or frictional heat in the ball

bearing. The oils are divided into mineral and synthetic oils. Animal or

vegetable oils are not suitable or only suitable to some extent for use in ball

bearings. In total, more than 400 lubricants are used in GRW and, therefore,

cover a large area of use, from the food industry to aviation and

spaceflight.

Various types of shileds in ball bearings Finally, the

shield is mounted on the ball bearing as the last component. This should keep

the impurities away from the high precision functional surfaces of the bearing

and, therefore, produce as little friction as possible. On the other hand, this

should keep the lubricant in the bearing. Impurities that get between the ball

and the raceway will tip over and damage the processed tracks. To avoid this,

contactless protectors and contact protectors are offered, with various sealing

qualities.

carbon steel balls, chrome steel balls, stainless steel media, stainless media, zirconium beads

carbon steel balls, chrome steel balls, stainless steel media, stainless media, zirconium beads

With contactless protectors there is no increase in torque,

since the protector creates a separation ring. It does not produce friction

and, therefore, can be used even at the highest speeds.

With the contact protector, the so-called ball bearing seal

touches the shoulder of the inner ring with a defined contact pressure and,

therefore, causes a greater moment of friction. Compared to contactless

protectors, all contact protectors will wear out over time. Dust protectors are

mainly produced from stainless steel or Perbunan rubber reinforced with steelsheets. The established seals are made of a fiberglass reinforced Teflon disc

or a synthetic fluorine rubber reinforced with steel sheets. In total there are

63 shield variants to choose from.

alumina ball, bead media, glass bead media, catalyst media, stainless steel balls

alumina ball, bead media, glass bead media, catalyst media, stainless steel balls

At GRW, individual products are made of these components for

the customer's special requirements. Due to a sensible combination strategy of

standard and special components, GRW can satisfy the most diverse market requirements

and guarantee our customers a competitive advantage.

The extensive and competent advice and design of a ball bearing are the prerequisites for the highest compliance with the established

requirements. Even in the development phase of new applications, GRW engineers

can provide valuable technical information and, for the most part, also cost

savings.